Black cumin oil exctraction

There are various technologies how to extract black cumin oil

1. Cold Pressing

Oil can be extracted from Nigella sativa seeds by using the different methods. The cold pressing method is suitable for extracting Nigella sativa oil from seeds. In this method, mechanical pressing was used for the pressing of seeds at a temperature of 25 °C. Furthermore, the separation of oil and crushed seed fiber has been performed by soaking the solution for one night at a 25 °C temperature. After that, filtered oil was obtained by using a glass funnel and Watman #4 filter paper.

2. Supercritical Fluid Extraction

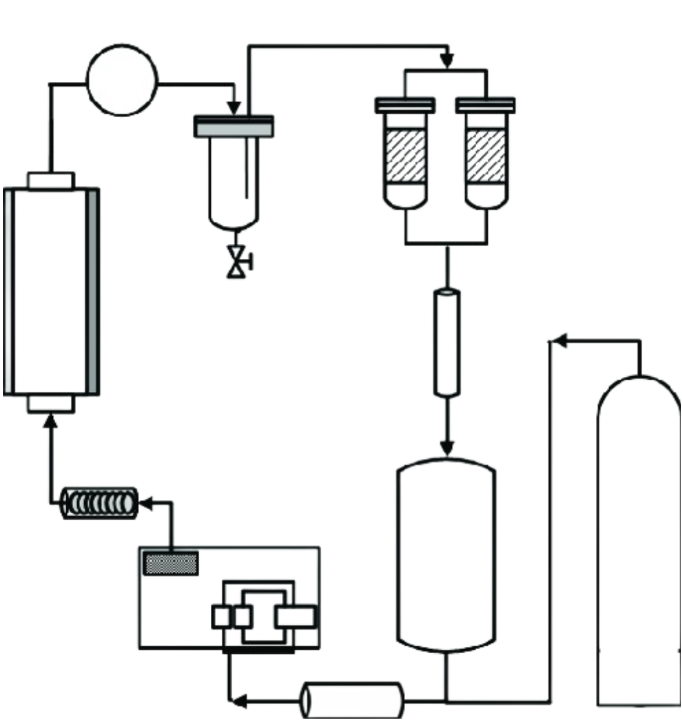

Another innovative method for the extraction of Nigella sativa oil from seeds. The supercritical fluid extraction equipment was used for Nigella sativa seed oil extraction, by using a stainless steel grinder for 3–4 min; the crushed dried seeds were obtained, placed the material in a 50-L container of extractor, and sealed tightly. The system used an automatic back pressure regulator for maintaining the temperature at 40 °C for 1 h; the pressure was 600 bar, and the flow rate of injected liquid carbon dioxide (CO2) was 150 L/h.

In the other way of supercritical fluid extraction method for Nigella sativa seed oil extraction. In its instrumentation, it contained a syringe pump with 260 mL capacity, controller system (ISCO 260D), and ISCO series 2000 SCF extraction system (SFX 220), consisting of a dual chamber extraction module with two 10 mL stainless steel vessels. Hence, about 5 g of ground black seeds were added in a stainless steel cell (10 mL). Then, the standard quantity of supercritical carbon dioxide (SC CO2) (50–400 mL) was flushed into the cell at a 1 mL/min flow rate. The final concentration of the extract was collected in the cold trap. After optimization of supercritical fluid extraction conditions, the lower yield of 0.84% (508 °C, 400 bar, and 100 mL) and higher yield of 31.7% (508 °C, 100 bar, and 200 mL) were obtained at optimum levels.

3. Soxhlet Extraction

Used the soxhlet apparatus for Nigella sativa oil extraction from black seeds. For this purpose, Nigella sativa seeds were collected from different regions of India, including Tamil Nadu, Triplicane, and Chennai. During the sieving process, the small and contaminated seeds were removed at room temperature. In this process, the seeds were first ground using a tabletop mixture, hexane was used for extraction of seed oil for approximately 2 h in a soxhlet apparatus, and the extracted oil was stored at room temperature in a selected amber glass bottle until use. Nigella sativa seed has 28–35% fixed oil, which mainly consists of unsaturated fats. Through gas chromatography–mass spectrometry (GC-MS) analysis, 32 different compounds were found in black seeds.

4. Hydro Distillation (HD) Method

The hydro distillation (HD) method for the extraction of oil from Nigella sativa seeds. In the first step, the seeds were ground at 25 °C. Then, they weighed the 70 g sample to be used for further analysis. The average yields were achieved and figured on a dry weight basis. For attaining essential oil through the HD method, they used a water holding flask for placing the material. It is called a Clevenger-type apparatus because the flask is directly connected to the condenser. After 2 h of continuous processing, a yield of 0.29 wt/wt of pale-yellow oil was obtained.

5. Microwave-Assisted Extraction (MAE)

Interesting approach is the oil extraction through a domestic microwave oven with a frequency of 2450 MHz. Initially, they took 50 g of ground seeds and selected a 500 mL round-bottomed flask for the soaking of seeds in 50 mL of water for about half an hour. After that, the Clevenger apparatus was fixed with a flask and utilized 450 W of power for heating (30 min). However, the essential oil was leached out in the n-hexane solvent. Only 0.33% essential oil yield was achieved by using MAE extraction conditions (power 450 W, moisture content 50%, and time 30 min).

6. Ultrasound-Assisted Extraction

An ultrasound-assisted extraction method for oil extraction. For one treatment, a sample of 500 g was transferred to the 1.5-l container that was placed in the ultrasonic bath. Several optimization conditions were selected, including the time (30, 45, and 60 min) and ultrasound pretreatment power (30, 60, and 90 W) at a fixed frequency of 25 kHz. After completing this process, the oil was isolated by using a screw press at 33 rpm speed. The maximum results of 39.93% extraction efficiency were achieved at power of 90 W and time of 60 min, while the minimum results of 27.29% extraction efficiency were achieved at power of 30 W and time of 30 min.

7. Steam Distillation

For the prevention of the side effects of degradation, steam distillation was performed at a low temperature. In 100 mL of distilled water, 10 g of seeds were added and mixed. This mixture was quantitatively transferred into the separatory funnel. This process of extraction was performed three times; a total of 10 mL of diethyl ether was added at every step, and the funnel was shaken vigorously. Sodium sulfate was used to dry the organic layer, and 0.4% was the obtained yield after evaporation in the water bath. A glass column-containing material was interpolated between the condenser and flask. The yield of oil that was extracted by steam distillation was 0.39%, and the color of the oil was pale yellow.

8. Accelerated Solvent Extraction (ASE)

A 1 g sample of black seeds in powdered form was taken in a stainless steel cell with a 34 mL capacity. The conditions were set: 100 atm pressure, 10 min static time, 20% rinse volume, 2 extraction cycles, 30 s purge time, and 26 mL of solvent volume. P1-P9 black seed samples from Pakistan, Indian, and Saudi Arabian were treated with n-hexane as P1-P3, methanol (MeOH), and dichloromethane (DCM) at 40 °C, P4-P6 with MeOH, DCM, and n-hexane at 50 °C; the same procedure was performed for P7-P9 at 70 °C. The results reveal that the solvent with high yield, following n-hexane, was MeOH, whereby the yield and recovery observed was 2.5 g (12.5%) for Saudi Arabia, 2.2 g (11%) for Pakistan, and 2.04 g (10.2%) for Indian black seed sample.